Case hardening is an important heat treatment process that provides steel gears and other transmission components with a hard surface and a comparably soft core.

This enables them to resist high surface pressures while ensuring a long fatigue life. Yogesh Patil, General Manager of the Ovako Group, India, explains how it works.

Case hardening is used to produce a hard, highly resistant surface layer and a tough core.

After case hardening, the surface layer contains substantial compressive stresses.

The process is often used for applications like gears where the loading produces high surface pressure in combination with fatigue stresses.

Case hardening consists of two separate treatment stages. Sometimes, they are performed in direct succession. In the first stage, some form of carbon is added to the surface layer of the material. In the second stage, hardening is performed.

The article covers different stages of cases hardening through various techniques.

Low-alloyed steel is often used in case hardening, typically featuring a carbon content ranging from 0.15 to 0.25%. In principle, any steel with less than approximately 0.8% carbon content can undergo case hardening.

However, it’s essential to note that beyond this threshold, many of the benefits associated with case hardening start to disappear. Carburizing involves the addition of carbon to the surface layer of the material.

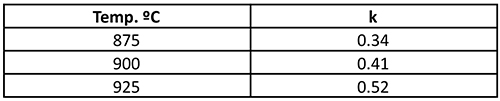

The thickness of the carburized surface layer is controlled by the diffusion of the carbon in the austenite, which is the face-centred cubic (FCC) crystalline structure of the material at the carburizing temperature (850 to 950°C). The diffusion speed is roughly dependent on temperature and time.

The carburizing depth attained can be calculated approximately as:

X = k.√t

Where:

X = case-hardening depth (mm); t = time in hours;

k = is determined by the temperature.

As an example:

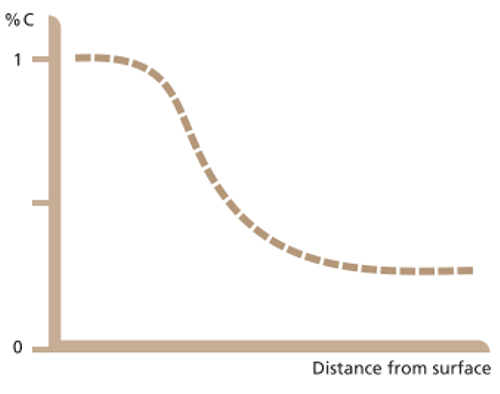

After carburizing, the carbon content varies as seen in Figure 1, and after hardening, the hardness achieved is therefore a function of the distance from the surface.

Figure 1: Relationship between carbon content and distance from the surface

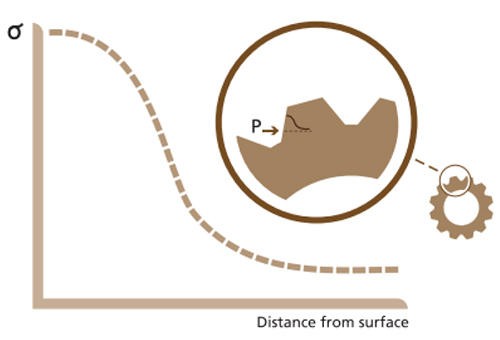

The load the component will be subjected to determines how deep the in-carbonization depth (depth of hardness after hardening) needs to be.

The tooth face of a cog, for example, transfers a certain load undergoes a strain that varies with the depth under the surface as shown in Figure 2.

The case-hardened layer must then be provided with a strength profile which at every point from the surface to the core corresponds to the load applied.

Figure 2: Shows how the stress varies according to distance from the component’s surface distance.

The processing stage in which carbon is added to the surface of the material is called carburizing or in-carbonization.

ln-carbonization occurs at high temperatures which can result in substantial grain growth. This grain growth can be effectively counteracted by using fine-grain treated material.

Occasionally, the material is normalized after carburizing. At present, three different methods are used to add carbon. Common to all of them is that the material used to envelope the material has a relatively high carbon content of about 1%.

Gas carburizing: It is the most common method used on an industrial scale and it offers major advantages from the standpoint of productivity and control.

Salt bath carburizing: It is performed in a cyanide salt environment and is primarily utilized when there is a need for a relatively small in-carbonization depth.

Powder carburizing: It is done by placing the component in a container packed with powder which is made up of a combination of wood carbon and barium carbonate. The process requires extensive manual handling.

The carbon in the surrounding atmosphere is absorbed relatively fast by the surface at the carburizing temperature, and the carbon then diffuses from the surface towards the core.

The term “gas carburizing” can be misleading since carburizing inherently involves a gas phase. Instead, “gas carburizing” refers to the method where the carbon-releasing agent is introduced into the furnace in gaseous form.

Various approaches can be employed for this purpose. One method involves producing a gas rich in carbon monoxide (CO) through the complete combustion of certain hydrocarbon materials.

Alternatively, some hydrocarbon that evaporates can be introduced into the furnace to achieve the desired effect.

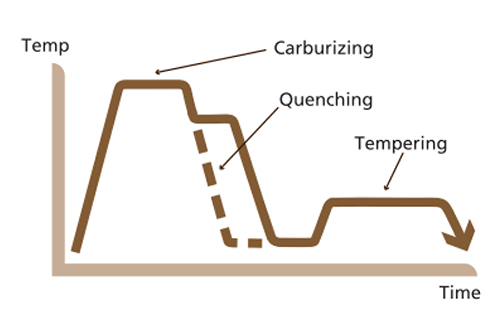

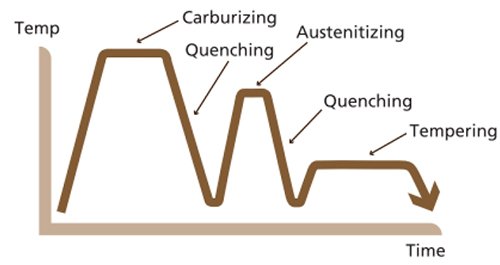

There are three different ways of hardening carburized material, and there are also variations in these methods.

Direct hardening: This involves hardening the material directly from the carburizing temperature.

Consequently, the austenitizing temperature is high, resulting in a coarse structure, especially in the high-carbon-content surface. It’s important to note that this method is rarely employed.

Direct hardening can also entail the rapid cooling of the material to suitable austenitizing temperatures for the high carbon content surface zone (620 to 850°C) after carburizing.

The temperature is allowed to become uniform throughout the component, and it is subsequently hardened to martensite.

This means that the core material does not receive the correct austenitizing process.

Direct hardening is very common among component manufacturers such as in the automotive industry.

Figure 3: Direct hardening

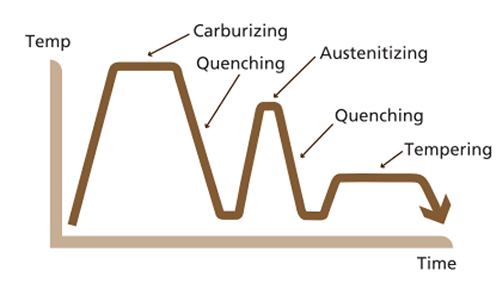

Single hardening: It implies that the material is cooled to room temperature without permitting martensite to form.

Afterwards, conventional austenitizing and martensite hardening are performed. Austenitizing is undertaken to attain optimum results in the surface zone.

Double hardening: This signifies that the material undergoes direct hardening immediately after carburization, followed by conventional martensite hardening.

In general, case hardening results in higher degrees of residual martensite than through hardening.

Direct hardening, following the adaptation of the hardening temperature, has become increasingly common and imposes considerable demands on the grain growth of the material.

Figure 4: Single hardening

Figure 4: Single hardening

While there is a strong relationship between a steel grade and how it can be heat treated, often the same type of heat treatment can be used on many different steel grades.

It is not possible to case-harden ball-bearing steel but both ball-bearing steel and hardened and tempered steel can be tough hardened.

However, it is easy to case-harden structural steel and hardened and tempered steel as well as carburizing- steel.

Therefore, the choice of steel grade combined with heat treatment provides some degree of freedom while designing the transmission components.

There is a singular crucial factor to consider: achieving the lowest cost for both the material and its heat treatment, all while ensuring that the final product meets all its specifications.

Ovako has created an online heat treatment guide to help design engineers evaluate the mechanical properties after quenching and tempering of any grade of steel that contains the 13 most common alloying elements.

This tool makes it possible to compare the heat treatment and tempering performance of thousands of steel alloys without the need for extensive desk research, calculations or testing.

While Ovako produces around 500–600 grades available as standard, there are many more specialist steel grades on the market. In theory, the number of grades is almost endless as steel properties vary depending on the alloying elements and their quantities.

Leveraging a neural network to simulate the performance of specific steel grades, comprehensive documentation exists regarding their hardenability throughout heat treatment and tempering.

This valuable insight has been made possible through extensive laboratory testing, resulting in a repository of properties for widely recognized grades.

You can access Ovako’s heat treatment guide through its online platform, Steel Navigator here: https://www.ovako.com/en/services/digital-tools/steel-navigator/

Yogesh Patil, General Manager, Ovako Group. He is a metallurgist with an expertise in alloy steel, and is a reliable guide for the selection & application of steel.

Yogesh Patil, General Manager, Ovako Group. He is a metallurgist with an expertise in alloy steel, and is a reliable guide for the selection & application of steel.