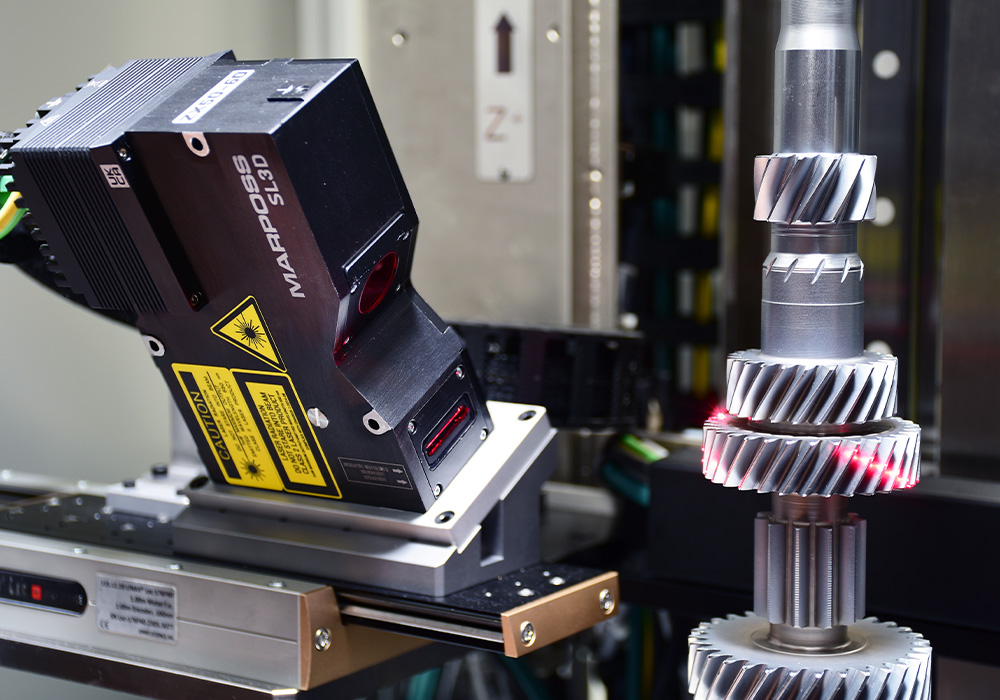

The OptoCloud’s main technology is the triangulation laser measurements made with Marposs’s new laser system.

Marposs introduces the OptoCloud GEAR, the newest member of the Marposs OptoCloud family. With the introduction of this new device, a profilometer-like tool can now be utilized for fast testing of various gears or shafts right on the shop floor and near the production line. As a result, logistic costs will be reduced, and the inspection chain will become shorter. This enables the prompt identification of manufacturing trends and more efficient application of necessary corrections.

The OptoCloud’s main technology is the triangulation of laser measurements made using Marposs’ laser system; the lack of contact between the measuring system and the part increases the inspection speed and removes wear of the measuring system.

As the popularity of electric vehicles continues to rise, manufacturers face the challenge of enhancing efficiency while maintaining high-quality standards. This involves shortening inspection times, enhancing gear quality, and ensuring cost-effectiveness. In addition, inspection systems must be adaptable to accommodate the constantly evolving components.

Marposs Opto product family including OptoFlash, OptoQuick, and OptoCloud products are suited to address these challenges. OptoFlash, available in different model sizes, is the best choice for inspecting products in different part sizes from 30mm to 300mm in an instant. OptoQuick is suited when you need flexibility in part inspection — additional sensors (3D Touch probes, followers, …) can be added to inspect every feature you want to keep under control. It can accommodate parts from 600mm to 1200mm and diameters up to 240mm. The OptoCloud family is the newest offering, with the EDU version already available for inspecting electric motor stators, providing 3D reconstructions, and measuring specific features such as hairpins. and the presence of the isolating paper.

For more information, visit us at our stand at EMO (Hall 6, Stand B52) or visit our website:

MARPOSS was founded in 1952. Mr. Stefano Possati is the President of the Group; it provides shop-floor solutions for measurement, inspection and testing in the production environment. Marposs’ solutions include gauging equipment of mechanical components, before, during and after the production process; monitoring solutions on machine tools; assembly and testing for many industry sectors; and automatic machines and inspection stations for production lines. MARPOSS is one of the main suppliers to the automotive industry providing solutions for both traditional and electric mobility but additionally operates in the aerospace, biomedical, hi-tech, white appliance,