Gears are essential in many industries including automotive, machinery, marine, aerospace, medical, and food processing. Although the gears used in these industries have very different designs, they all need to be manufactured in a time and cost-efficient manner.

In addition, the demands on the required surface quality are constantly increasing in order to reduce friction losses, improve NVH (Noise, Vibration, Harshness) properties, and increase the flank load capacity and lifetime of the gears in the final transmission.

The best NVH results of two meshing gears are achieved when different surface patterns are present on the flanks of both gears. If similar surface patterns were present on both gears, periodic vibrations as well as additional noise emissions could be caused, thus reducing the performance of the gears in the gearbox.

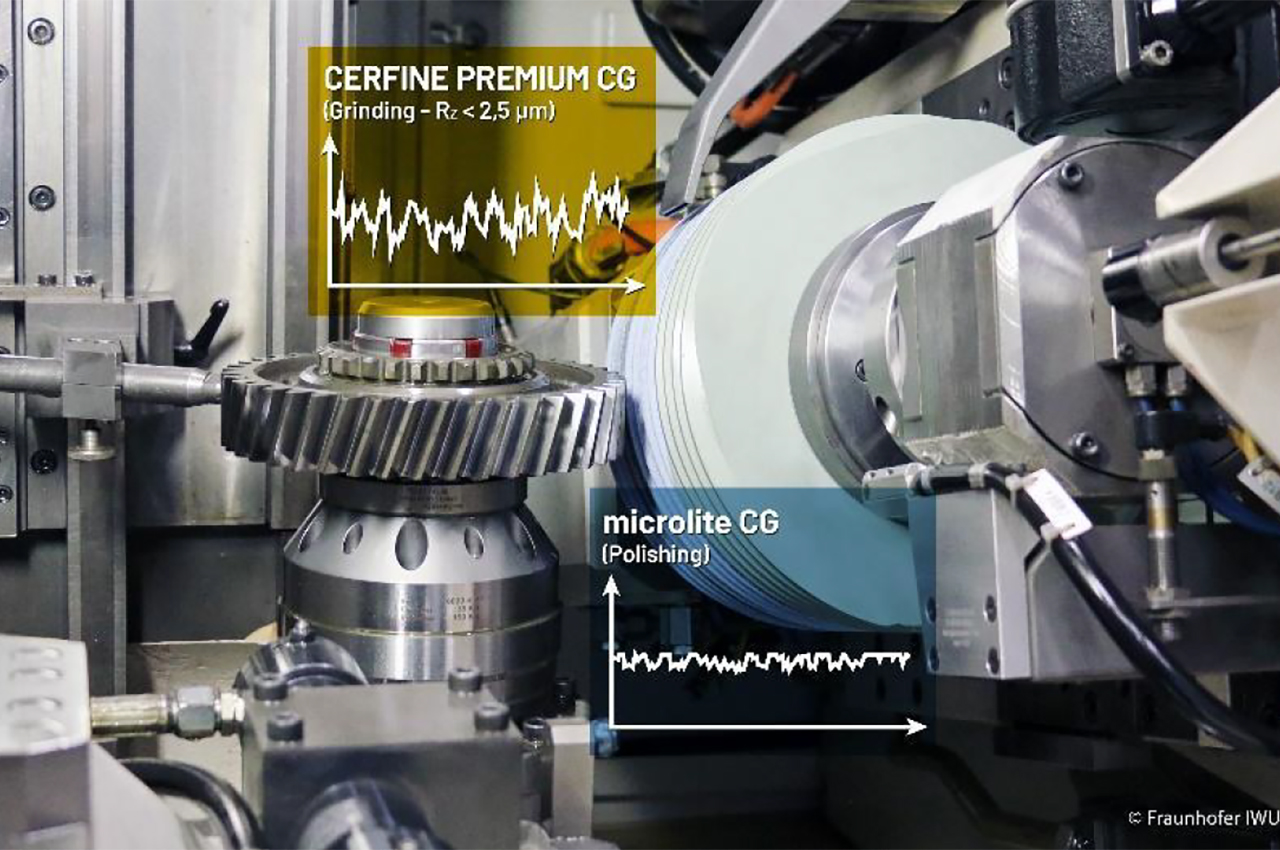

The surface structure of the gear flanks depends mainly on the utilized finishing process. Therefore, different finishing processes are recommended for the production of each of the two meshing gears.

However, the number of manufacturing processes capable of producing the required surface characteristics in a productive manner is very limited. Gear honing and continuous generating gear grinding are the most commonly used methods for industrial gear production.

Due to their very different process kinematics, both processes produce completely different surface patterns and can achieve very high surface qualities while being very economical compared to other manufacturing processes.

The main challenge for both processes is to find appropriate tool specifications and process parameters to achieve the most economical results while creating the desired surface finish.

Hermes Abrasives offers a wide range of different honing and grinding tools with the most competitive tool technology, i.e. the latest and most innovative VITRA-Bonding.

This technology makes it possible to achieve very high material removal rates while achieving the required surface quality.

In addition, the honing rings and grinding worms can both be made with Microlite, our first-class product for polishing of gear flanks.

This further enhances the surface quality and even allows to create reflective gear flanks! The individual tool design however strongly depends on the individual application case at the customer.

Hermes provides a wide range of customized tools combined with many years of experience and this allows to assist the customers with a special service in all aspects of gear grinding, from the process and tool design to the optimization of process parameters and the troubleshooting in case of bad gears.

If you need assistance with your honing or gear grinding process, please contact your nearest

Hermes office or visit us at

https://www.hermes-abrasives.com

National Distributors for India:

Dev Abrasive Pvt. Ltd.

7455888384/ 7455888386

Tel: 022-28828419/ 28812186 /2880 4825

Address:

Works: 79, Shiv Ganga Industrial Estate, Lakeshwari, Bhagwanpur, Roorkee, 247667. INDIA.

Off: 501, Vakratund Corporate park, PMP Road, Goregaon East, Mumbai 400063 INDIA