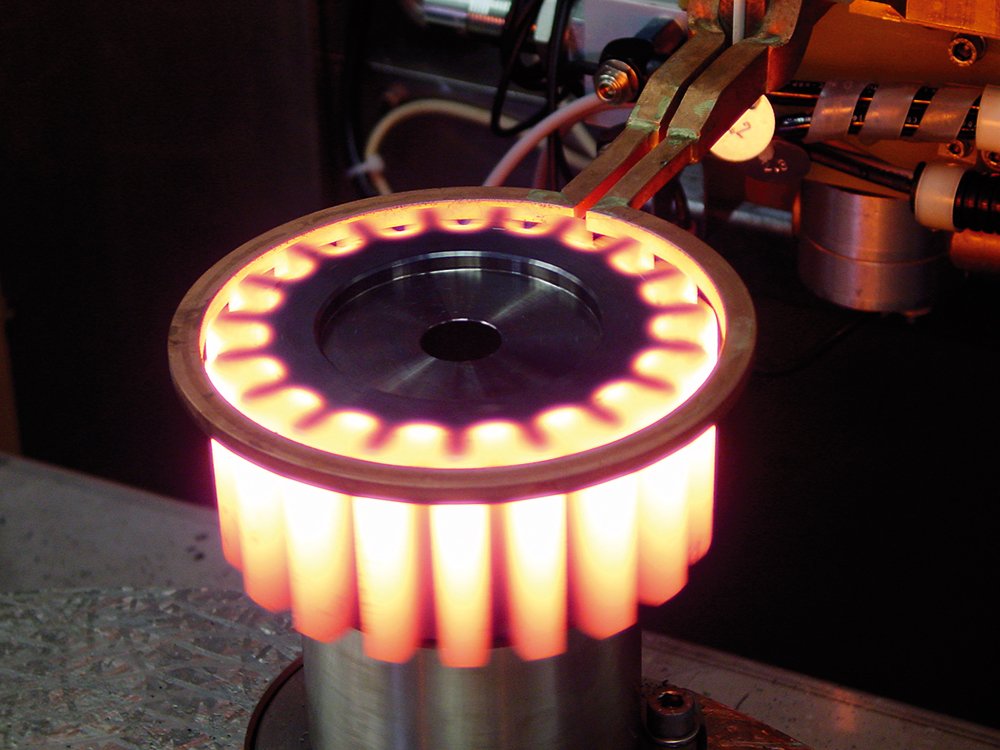

Thanks to its efficiency, versatility and meticulous control over hardness patterns, induction heating is the best choice for attaining optimal performance and enhanced durability in gear manufacturing.

Gear Technology India spoke with Director for Sales & Marketing in Asia, Mahesh Gupta, about ENRX, their offerings, digitalization and more.

ENRX is the world’s largest induction hardening equipment maker. With more than 70 years of experience, the company offers solutions that boosts throughput, cut costs, and help manufacturers around the world to reach their productivity targets as well as their sustainability goals.

With a global footprint encompassing America, Europe, and Asia, ENRX’s influence spans continents. Their Indian base in Bengaluru KIADB aerospace park, coupled with sales and service hubs in Gurgaon and Pune, ensures a local touch for global excellence.

“When we harden gears with induction technology, we use induced heat and rapid cooling or quenching to increase the hardness and durability of the steel.

It is a no-contact process that quickly produces intense, localised, and controllable heat,” Gupta explains, elaborating on the many benefits the technology has to offer.

“First of all, it is extremely fast. ENRX’s patented simultaneous multi-frequency hardening process achieves true contour hardening of small gears in well under a second. Advanced coil design and process control software ensure short cycle times and precise repeatability.”

ENRX is formed by the recent merger of global industrial induction heating expert EFD Induction and the patent-dense wireless inductive charging and contactless power supply innovator IPT technology.

The company enjoys a strong backing from owner Arendals Fossekompani — a forward-looking investment company that focuses on energy and technology-related businesses for a greener economy.

“As a global green technology company on a mission to speed up the journey to a sustainable future, we offer inductive heating, charging, and power transfer with low or no carbon footprint,” Gupta says. “These technologies provide value to manufacturing and mobility applications worldwide.”

All of ENRX’s products boast high energy efficiency and a minimum of waste whilst being safe and easy to use. “Energy efficiency is our forte,” he underlines, “ENRX’s commitment to a greener future is etched in every product, designed for optimal power utilization and efficiency.”

Gupta’s observation that “induction heating is used to make everything from faucets to spaceships” captures the remarkable versatility of ENRX’s technology.

Their applications extend to renewable energy production, where they are the world’s leading supplier of heating solutions for wind farms and power stations.

Brazing, welding, hardening and shrink-fitting — induction reverberates across a diverse range of industrial applications.

With an array of induction heating equipment that seamlessly adapts to this myriad of applications, from standalone tools to integrated systems, ENRX delivers optimal performance and endurance.

From automotive giants to electrotechnical powerhouses, induction heating is a cornerstone of manufacturing, also for major tube and pipe manufacturers, HVAC manufacturers and many other industrial segments worldwide

A surge in applications within renewable energy components further underlines its significance. “Notably, the shift from gas heating to induction heating in production processes significantly curbs carbon dioxide emissions,” Gupta underscores.

The integration of Industrial Internet of Things (IIoT) facilities in gear manufacturing has transformed the industry by seamlessly enabling data-driven decision-making, process optimization, and enhanced productivity.

“All our machines and power sources are now fitted with programmable logic or micro controllers enabling real-time operation, process monitoring, and remote diagnostics,” Gupta says and elaborates, “We’ve made our products ready for Industry 4.0. The equipment can be connected for performance analysis, error diagnosis and software updates.”

ENRX’s commitment to efficiency precision, and productivity finds its zenith in automation. “Our heating machines,” Gupta reveals, “operate with a choreographed precision, whether handling individual components or orchestrating continuous processes. Our automation ensemble extends to robots, gantries, and more, all tailored to meet specific customer needs.”

The quality of the induction heating process hinges on multiple variables such as power, frequency, voltage, and current, as well as cooling water flow and temperature. Each need to be accurately measured, compared against set limits, recorded, and controlled.

“Inputs for each manufactured component are digitized and fed into controllers for processing and recording,” Gupta explains. “Components which vary from the safe zone are quarantined.” Power source control and diagnosis is also fully digitized.

Integrating data-driven insights into manufacturing is a crucial component that enables manufacturers to consistently produce high-quality products. “Most of the critical movements in our machine rely on servo motors and ball screws,” Gupta notes.

“We also use multiple pumps for cooling water and lubrication. We can measure the current and temperature of all motors in our machines to ascertain their working condition and setting pre-emptive warnings for assessment during preventive maintenance. In addition, we monitor

end-of-life of tooling and proactively prompt operators for timely replacements.”

“ENRX will soon launch an online service and we are creating the necessary tools and software to ensure streamlined and efficient support and service.

This move is backed by our comprehensive shift to digital technology across our entire product lineup, including the provision of upgrade kits for older operational equipment on-site,” Gupta says, adding that this endeavour includes the rollout of a customer portal for seamless case management and tracking, as well as the integration of Augmented reality (AR) and Virtual Reality (VR) systems to facilitate clear communication, remote product upgrades and equipment condition monitoring via the web.

Customers can conveniently view the condition and performance data of their equipment on any internet-connected devices.

“If we want to stay in business, we have to base our operations on long-term commitments,” Gupta states. “So, we design our equipment with energy, water, and space efficiency in mind.” ENRX offers an array of products and systems that encompass the realms of heat, charge, and power, all designed to fuel eco-conscious industrial production and facilitate environmentally responsible transportation modes encompassing air, road, and rail.

“We take our Environmental, Social, and Governance (ESG) responsibilities very seriously,” he adds. “The global challenges we face today find resonance in the United Nations’ seventeen sustainable development goals,” he observes.

“While they are all interconnected, ENRX has chosen to focus on four that we think are the most relevant to our company and the business segments in which we operate: Promoting decent work and fostering economic growth, spearheading industry, innovation, and infrastructure, championing responsible consumption and production, and making substantial strides in climate action.”

Mahesh Gupta, Director – Sales & Marketing (Asia) ENRX Private Ltd (Formerly known as EFD Induction Private Ltd)

Mahesh Gupta, Director – Sales & Marketing (Asia) ENRX Private Ltd (Formerly known as EFD Induction Private Ltd)