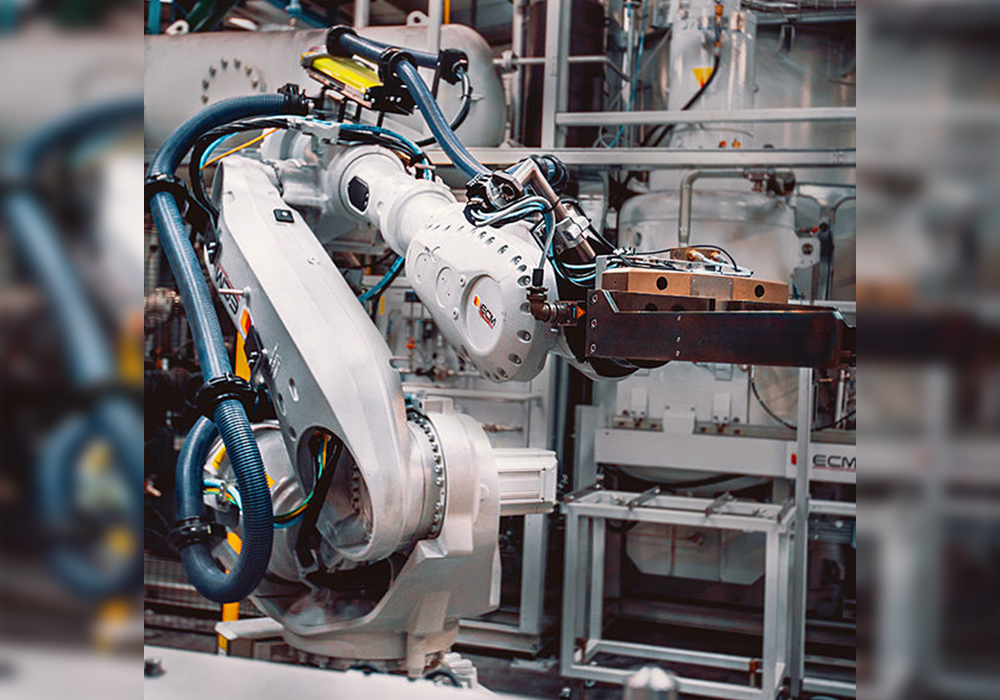

ECM USA has collaborated with the renowned global manufacturer SEW-EURODRIVE to install an advanced NANO vacuum furnace system at their Lyman, South Carolina facility. This marks the third ECM NANO system featuring integrated robotics and advanced capabilities for the US heat treat market in the past two years. The 6-chamber, 20-bar quench NANO vacuum furnace system is designed for maximum flexibility and integration, incorporating 16 tempering positions, an advanced solvent-based washer for both oil and water-based contaminants, and robotic workload assembly/disassembly. The system includes automated dunnage management within the robotics configuration and is specifically engineered to handle multiple materials, such as carburized grades and tool steels. Its modular flexibility allows adaptation to increased production for various load scenarios and processes. The incorporation of SEW-EURODRIVE’s Movitrans, a patented inductive energy power transfer supply system, further enhances ECM’s vacuum furnace transfer system. As the industry’s demand for automated solutions rises, ECM continues to surpass heat treatment production expectations with innovative technology, efficient equipment, and exceptional service.