By: Sushmita Das

Bonded abrasives play an important role in the precision-driven world of gear manufacturing. Gear industries rely on these abrasive tools to achieve the desired surface finish and dimensional accuracy in their products. Here, we look at the crucial role of bonded abrasives in gear manufacturing, and how they facilitate the process of surface grinding.

Gear manufacturing demands an unparalleled level of precision. Whether it’s in the automotive, aerospace, or industrial sectors, gears are vital components in countless machinery and vehicles.

To ensure optimal performance and longevity, gears must have smooth, precise surfaces that minimize friction, noise, and wear. This is where surface grinding comes into play.

Surface grinding is a machining process that involves removing material from the gear’s surface using abrasive particles. The primary goal is to create a high-quality surface finish, ensure dimensional accuracy, and produce gears that meet stringent industry standards. Achieving these objectives relies heavily on the choice of abrasive tools, and this is where bonded abrasives come to the forefront.

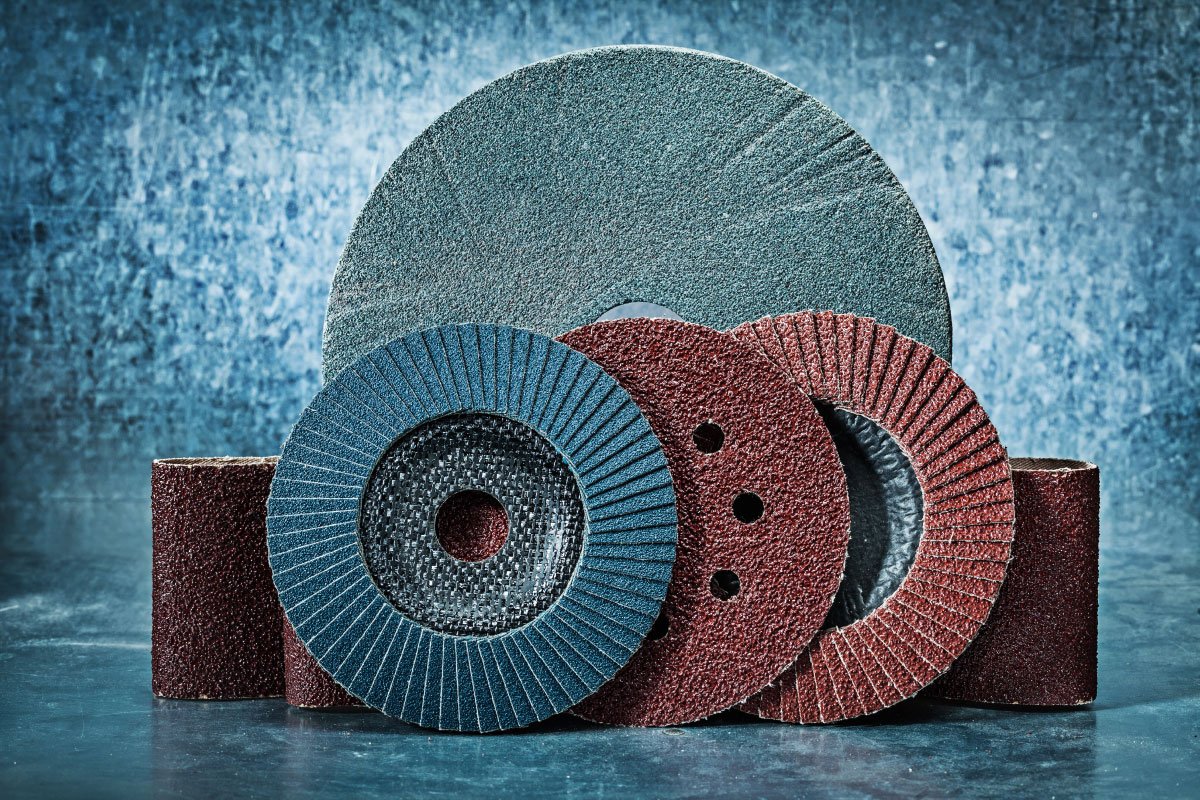

Bonded abrasives are abrasive tools made by mixing abrasive grains with bonding agents (usually resin, ceramic, or vitrified materials) and shaping them into grinding wheels, stones, or segments. These tools are tailored to specific applications and are ideal for precision grinding in gear manufacturing. Here’s why they’re indispensable:

Material Versatility: Bonded abrasives can be formulated to work effectively on a wide range of materials, including steel, aluminium, and hardened materials, commonly used in gear manufacturing.

Precision and Control: The abrasive grains in bonded abrasives are precisely oriented and held together firmly by the bonding agent. This ensures a consistent, controlled material removal process, crucial for creating gear surfaces with minimal deviations.

Cool Grinding: Many bonded abrasives are designed to generate less heat during grinding, preventing workpiece distortion and maintaining the integrity of heat-treated gears.

Longevity and Efficiency: The durability and longevity of bonded abrasives result in fewer tool changes and downtime, optimizing the grinding process in gear manufacturing.

Tailored Solutions: Manufacturers can choose the specific type of bonded abrasive based on their unique gear production needs, ensuring a perfect match for the job at hand.

Conclusion

Bonded abrasives are invaluable tools for surface grinding. They contribute significantly to achieving the desired surface finish, dimensional accuracy, and overall gear quality.

As gear industries continue to advance, the innovative development and application of bonded abrasives will play a critical role in perfecting the art of surface grinding and ensuring the reliable operation of machinery across various sectors.