In the ever-evolving landscape of manufacturing, robotics and automation have emerged as transformative technologies, revolutionising various industries. One such domain that has witnessed significant advancements in gear production. Robotics and automation have paved the way for more efficient, precise, and cost-effective methods of manufacturing gears, and essential components in machinery across numerous sectors.

In this blog, we shall discover how robotics and automation are streamlining the manufacturing process while improving precision and also learn the pivotal role played by robotic arms, CNC machining, and automated assembly in enhancing gear production processes.

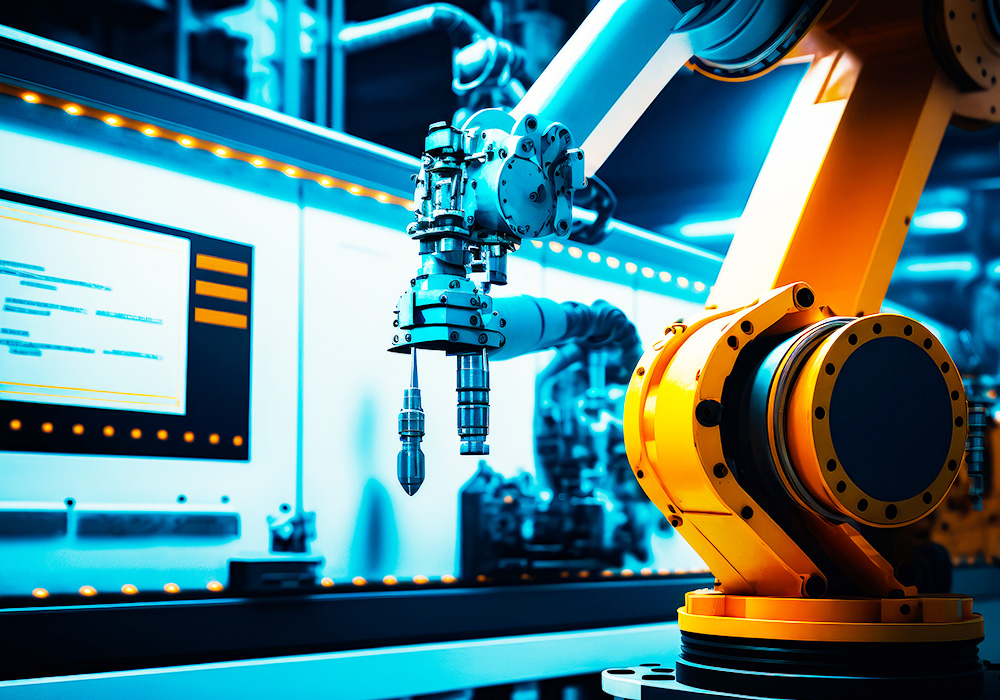

Robotic arms have become indispensable assets in modern gear manufacturing facilities. These highly versatile machines excel in tasks that demand precision, repeatability, and adaptability. In gear production, robotic arms are utilised for a myriad of functions, including machining, inspection, assembly, and handling of components.

One of the key advantages of robotic arms lies in their ability to perform complex tasks with utmost accuracy. Equipped with advanced sensors and vision systems, these robots can precisely manipulate gears of various sizes and shapes, ensuring consistency and quality throughout the production process. Moreover, robotic arms can execute intricate operations such as deburring, polishing, and surface finishing with remarkable efficiency, eliminating human errors and enhancing overall productivity.

Furthermore, robotic arms offer unmatchable flexibility in manufacturing operations. With the ability to swiftly switch between tasks and adapt to changing production demands, these machines enable gear manufacturers to achieve greater agility and responsiveness. Whether it’s producing custom-designed gears or rapidly reconfiguring production lines, robotic arms empower manufacturers to stay competitive in today’s dynamic market landscape.

Computer Numerical Control (CNC) machining has long been a cornerstone of gear production, and its synergy with robotics has elevated manufacturing capabilities to new heights. By integrating robotic arms with CNC machining centres, manufacturers can achieve an outstanding level of precision, efficiency, and automation in gear manufacturing processes.

CNC machining offers precise control over cutting operations, allowing for the creation of gears with tight tolerances and intricate geometries. Robotic arms complement this precision by handling workpieces with dexterity and positioning them accurately for machining operations. Whether it’s milling, turning, or grinding, the seamless coordination between CNC machines and robotic arms ensures optimal performance and minimal wastage of materials.

Moreover, CNC machining combined with robotics enables the production of complex gears that were once deemed impractical or cost-prohibitive. With advancements in multi-axis machining and robotic tool changers, manufacturers can now create gears with unconventional profiles and features, meeting the evolving demands of diverse industries.

In gear manufacturing, assembly is a critical stage where precision and efficiency are paramount. Traditional assembly methods often involve manual labour, which can be labour-intensive, time-consuming, and prone to errors. Nevertheless, with the advent of automated assembly systems, gear manufacturers can streamline production processes and enhance overall efficiency.

Automated assembly systems leverage robotic arms and advanced algorithms to assemble gears with unparalleled accuracy and speed. These systems are capable of handling various components, such as shafts, bearings, and housings, and assembling them into finished gear units with precision-guided movements. By eliminating manual intervention, automated assembly not only reduces labour costs but also minimizes the risk of defects and rework, ensuring consistent quality in every gear produced.

Moreover, automated assembly systems offer scalability and adaptability to evolving production demands. Whether it’s ramping up production volumes or integrating new components, these systems can be easily reprogrammed and reconfigured to accommodate changes, thereby future-proofing gear manufacturing operations.

In the dynamic realm of manufacturing, the integration of robotics and automation has heralded a new era of efficiency, precision, and innovation, particularly in gear production. The insights shared in this exploration underscore the transformative impact of robotic arms, CNC machining, and automated assembly on the manufacturing landscape, elucidating their pivotal roles in advancing gear production processes.

Robotic arms, with their unparalleled precision and flexibility, have emerged as indispensable tools in modern gear manufacturing facilities. Their adeptness in executing complex tasks with utmost accuracy, coupled with the ability to seamlessly adapt to changing production demands, has revolutionized gear production. From machining and inspection to assembly and handling, robotic arms epitomize efficiency, consistency, and quality, thereby empowering manufacturers to stay competitive in today’s dynamic market environment.

The synergy between CNC machining and robotic arms represents the epitome of precision engineering in gear manufacturing. By harnessing the precision of CNC machining and the dexterity of robotic arms, manufacturers can achieve unprecedented levels of accuracy and efficiency in creating gears with tight tolerances and intricate geometries. This synergy not only optimizes performance but also expands the realm of possibilities, enabling the production of complex gears that were once deemed impractical or cost-prohibitive.

Moreover, the advent of automated assembly systems has revolutionized the assembly stage of gear manufacturing, streamlining processes and enhancing overall efficiency. By leveraging robotic arms and advanced algorithms, automated assembly systems ensure the precise assembly of gear components with unmatched speed and accuracy. This not only minimizes labour costs but also mitigates the risk of defects and rework, thus ensuring consistent quality in every gear produced.

In conclusion, robotics and automation have emerged as catalysts for innovation and advancement in gear production, reshaping traditional manufacturing paradigms and unlocking new possibilities. As technology continues to evolve, the symbiotic relationship between human ingenuity and machine precision will undoubtedly drive further enhancements in gear manufacturing, propelling industries towards greater efficiency, reliability, and competitiveness in the global market landscape.