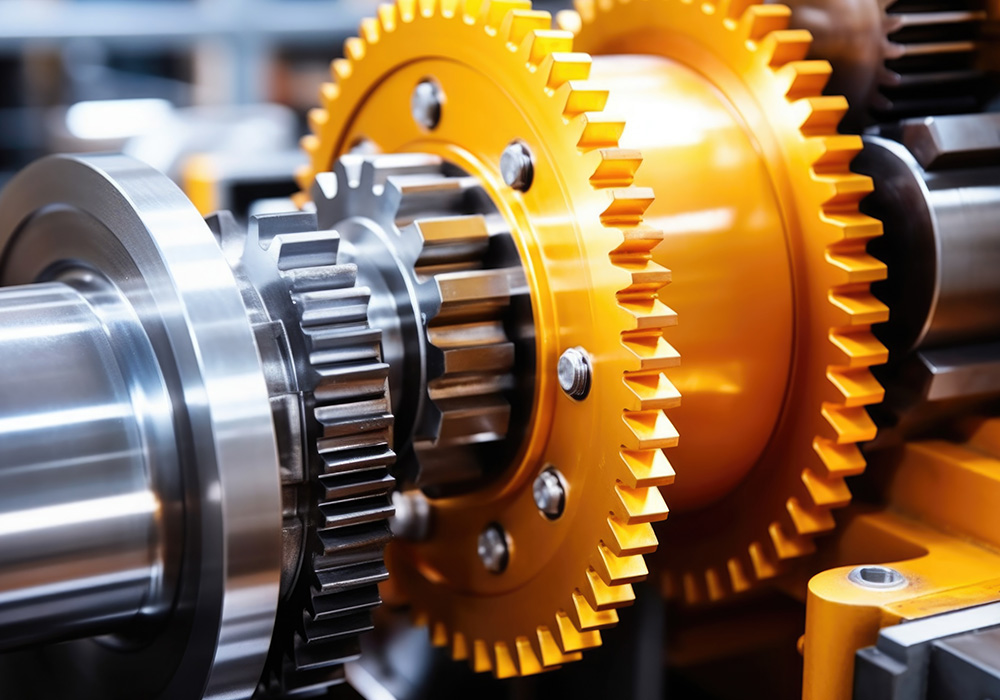

Gears are mechanical components with toothed surfaces that mesh with each other to transmit motion and power between rotating shafts. They are fundamental elements in countless mechanical systems, playing a critical role in various applications across industries.

At their core, gears function to transmit motion and power from one shaft to another. When two gears mesh, the rotation of one gear causes the other gear to rotate, thereby transferring motion and torque. This mechanism allows gears to change the speed, direction, and torque of rotational motion, making them indispensable in many mechanical operations.

Gears are universal in machinery and mechanical systems, serving countless functions. One of their primary roles is speed regulation, where they can either decrease or increase rotational speed between input and output shafts. Additionally, gears play a vital role in torque amplification, enabling the transmission of higher or lower levels of force between shafts. Gears also facilitate directional changes in rotational motion, offering solutions for scenarios where shafts are not parallel. Furthermore, gears are instrumental in motion synchronisation, ensuring the smooth and coordinated operation of multiple components within a system.

In manufacturing processes, gears are indispensable components utilised across various machines and equipment, facilitating efficient production in different industries. Machine tools, including lathes, milling machines, and gear-cutting machines, heavily rely on gears for precise motion control and power transmission during cutting, shaping, and finishing operations. Gears enable these machines to execute intricate machining tasks with accuracy and consistency, contributing to the quality and precision of manufactured parts. Additionally, gears play a pivotal role in industrial automation by ensuring the accurate positioning and movement of robotic arms, conveyor belts, and other automated components in manufacturing systems. They are integral components in engines, transmissions, steering systems, and propulsion mechanisms, where they facilitate the transfer of motion and torque to drive vehicles and aircraft efficiently.

Gears can be divided into three categories based on their orientation of axes;

Parallel axes gear, intersecting axes gear, and Non-parallel and non-intersecting axis gear. Let’s that a look into it:

Parallel Axes Gear: This is a type of gearing system where the axes (or shafts) of two or more gears are positioned parallel to each other. These gears have teeth that are cut parallel to the axis of rotation, allowing them to mesh smoothly and transmit motion and power between the rotating shafts. Parallel axes gears include spur gears and helical gears.

Intersecting Axes Gear: This is a type of gearing system where the axes (or shafts) of two gears intersect or cross each other at a point. These gears are designed to transfer motion and power between shafts that are not parallel but intersect at an angle. Examples of intersecting axe gears include bevel gears and spiral bevel gears.

Non-parallel and non-intersecting axis gear: Non-parallel and non-intersecting axes gears refer to a type of gearing system where the axes (or shafts) of two gears neither run parallel nor intersect each other. Instead, they are positioned at different angles, allowing for the transfer of motion and power between them.

Special Gear: Special gears refer to types of gears that are designed for specific applications or to meet particular requirements beyond those of standard gears. These gears often have unique features or configurations tailored to address specific challenges or performance criteria. Here are a few examples of special gears:

Gear manufacturing encompasses a wide array of essential components and processes that are fundamental to countless mechanical systems across various industries. From transmitting motion and power between rotating shafts to enabling speed regulation, torque amplification, directional changes, and motion synchronisation, gears play a critical role in ensuring the efficient operation of machinery and equipment.

The significance of gears in both mechanical systems and manufacturing processes cannot be overstated, as they contribute to enhancing productivity, precision, and reliability. Understanding the different types of gears, including spur gears, helical gears, bevel gears, worm gears, and hypoid gears, as well as special gears like planetary gears and face gears, is crucial for designing and manufacturing systems tailored to specific requirements and performance criteria. By exploring the diverse applications and functionalities of gears, manufacturers and engineers can continue to innovate and advance the capabilities of mechanical systems, driving progress and innovation in various industries. Stay tuned for the next part!