Roll Testing

By: Dr.-Ing. Alexander Landvogt, and Thomas Serafin

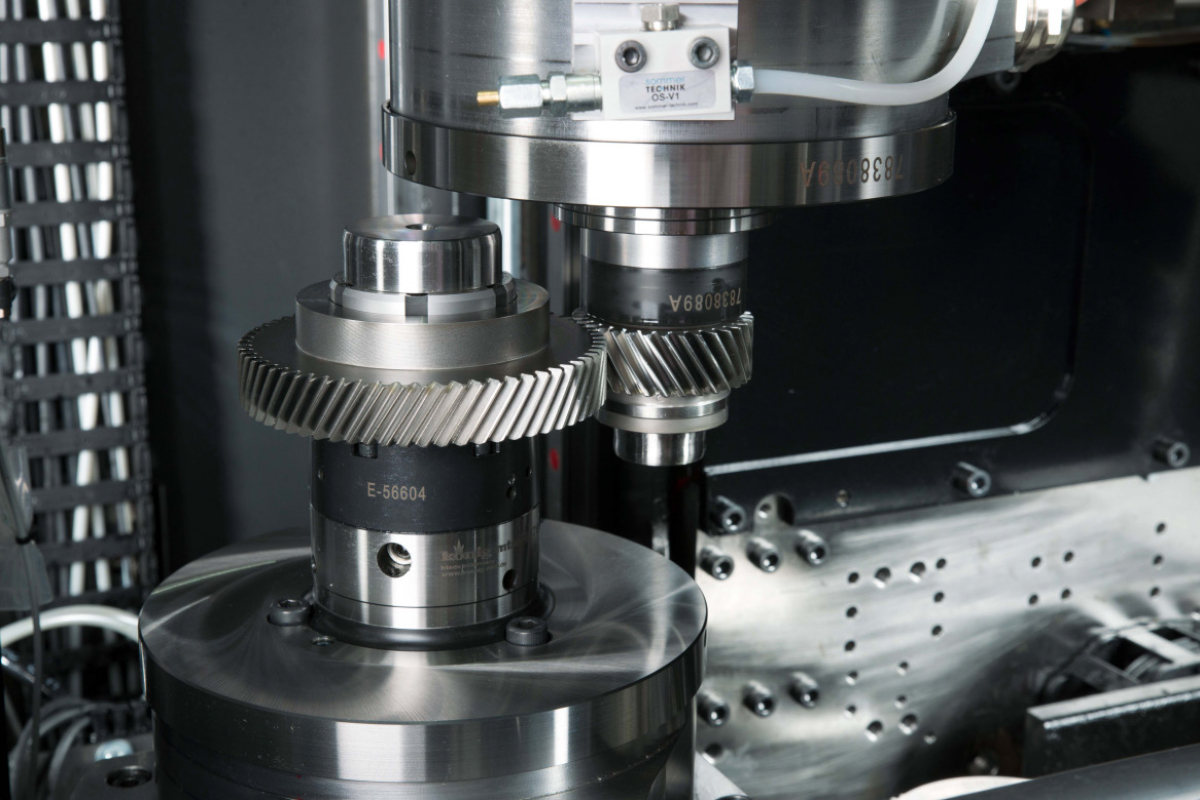

The measuring technology on the Höfler R 300 Cylindrical Gear Roll Testing Machine provides a reliable way to determine the root causes of gearbox noise. Due to the short measuring time, it can be easily integrated into any manufacturing process.

The more precisely a gear is manufactured, the better its running behavior will be. This is true for the working load limit of a gear, but not to a gear’s noise emissions.

Thus, gears with almost identical results in pitch, profile and tooth flank measurements can differ significantly in terms of noise behavior in the gearbox.

The result can be heard right away – but finding the root cause is not so easy.

There seem to be many causes for gear noise, but it actually always boils down to vibration of the gear elements under load. The noise behavior is mainly determined by vibrations resulting from tooth contact.

Starting from the tooth contact, these vibrations are transmitted to the gearbox housing surface as structure-borne noise and radiated from there as audible airborne noise.

The “sore point” in production is not the running behavior resulting from the design, but the fluctuations in noise results on the end-of-line (EOL) test rig. If unacceptable noise behavior occurs here, a very complex root cause analysis of all components is required.

Often the unpleasant noise can then only be ”miraculously” eliminated by replacing individual components. This accounts for the increasing need to predict noise for each individual gear even before assembly.

Because there are many variables influencing the transition from vibrations to airborne noise, a simple geometric consideration of the gear deviation is not sufficient for noise analysis. Here, suitable measurement methods and special evaluation procedures are required to get to the bottom of the noise.

When it comes to improving noise behavior, a general distinction is made between primary and secondary measures.

Fig. 1: Interaction between tooth flank geometry, load influences and attenuation

Primary measures minimize the excitation behavior, while secondary measures improve the transmission path from excitation to the generation of airborne noise. The rest of this article will focus on the primary measures.

Figure 1 shows how manufactured tooth flank form, load influences and attenuation interact.

So where can we start to get a clear picture of a gear’s noise behavior in series production? Keeping in mind the reality of manufacturing, variations in material characteristics and variations in attenuation behavior in the gearbox can be ruled out.

Consequently, the tooth flank is the only thing remaining that is allowed to change within the tolerance specifications for manufacturing.

And that’s the good news: With a load-free examination of the tooth flanks, almost all effects on gear noise caused by tooth contact can be detected.

The single-flank test is a method that has been used for decades to evaluate the quality of the rotary transmission or running behavior of two gears.

To test the running behavior, the gear is generated with a precisely manufactured master gear.

Due to the low test speed, the single-flank test is highly reproducible, but it involves a longer measuring time.

The structure-borne noise measurement very closely approximates the noise behavior in the gearbox.

Instead of measuring the transmission error between the test gear and the master gear with high-resolution angular encoders, an acceleration sensor is used here to record the dynamic excitation from the tooth contact on the structure of the test rig.

Since this is done at much higher speeds compared to the single-flank test, the measuring time is relatively short.

In addition, there is also the rotational acceleration measurement, which instead of measuring the vibration excitation in all spatial directions, only measures those that act on the rotation of the test gear and master gear.

In purely mathematical terms, this is the second derivative of the single-flank test. All roll testing methods are characterized by the fact that all tooth flanks of the test gear undergo a function-oriented measurement.

Compared to 3D coordinate measurement, the effect of the geometry deviation on the function is evaluated and not the deviation compared to the nominal geometry.

However, only the areas of the tooth flanks that are in rolling contact with the master gear are evaluated.

By suitably designing the tooth flank geometry of the master gear, the area to be examined can be optimized to achieve an adequate correlation with the end-of-line (EOL) test rig.

Although the characteristic values of the gear geometry deviations are of secondary importance in roll testing, the results reflect the running behavior as closely as possible.

Instead of analyzing the transmission error or acceleration signals in the time domain, they are represented as an order spectrum using a Fourier transformation. In simple terms, an order spectrum indicates how often an irregularity occurs per gear revolution.

The magnitude of such an irregularity is expressed in the amplitude of the respective order (see Figure 2).

Runouts can always be found in the low orders. If eccentricity is the only irregularity on the gear, only the first order is present.

Fig. 3: Order spectrum, including the significance of certain orders

For example, in a gear with 15 teeth (see Figure 3), tooth contact occurs 15 times per revolution.

This is the reason for the 15th order. The amplitude of this order depends on the size of the tooth flank modifications defined in the design.The orders in the immediate vicinity of a tooth-mesh order originate from single pitch deviations and runout.

The prominent 38th order is a gost order.

Gost orders are orders that do not correspond to any multiple of the number of teeth. They are caused by manufacturing deviations that are not equally present on all teeth.

An order spectrum therefore offers deep insight into the quality of a gear’s transmission error, which is ultimately the cause of vibrations and the resulting noise.

In contrast to roll testing, the focus here is on the geometry of the gear. The gear measurement technique is used to detect the production-related geometric deviation of the pitch, the tooth flank in profile and lead direction, and to minimize it by means of corrections on the processing machine.

Although the gear measurement technique is called a function-oriented test, its validity is limited.

Fig. 4: Length of path of contact and profile measurement

The functional orientation is based on the distinctive characteristic of involute gears, whose contact points of the tooth flanks run along the so-called straight length of path of contact. (see Figure 4).

Fig. 5: Profile and flank line measurement on four teeth as well as pitch measurement

The key difference in comparison to roll testing is that line measurements in the profile and lead direction are used to draw a conclusion about the geometry of the gear (see Figure 5).

This assumes that when three or four teeth are measured on the perimeter, all teeth are essentially identical.

The indisputable advantage of the gear measuring technique is that it can be used to conclusively pinpoint manufacturing deviations, which in turn opens up possibilities for corrections.

In the design phase, tolerance widths for pitch, profile and lead are defined such that the theoretical running behavior will fall into the acceptable range. Thus, the running behavior is not explicitly tested.

Rather, it is assumed that the 3D surface tooth flank resulting from extrapolation of the measured profile and lead will exhibit precisely this behavior. But the conventional gear measuring technique reaches its limits in noise-critical applications. Profile and lead measurements are inadequate when it comes to identifying flank defects that are relevant to noise.

In addition to selective point and line measurement, limiting the measurement to three or four teeth on the perimeter introduces additional measurement uncertainty.

Nevertheless, geometry-based detection of noise excitation has not reached ist end. Measurable waviness that leads to vibrations when the tooth flanks are generated can be identified by a graphical comparison of measurement results on loud and quiet gears.

Quantitative analysis of waviness requires an evaluation method that allows the amplitude and frequency of the waviness to be reliably determined.

Since the waviness amplitudes are often in the nanometer range, measuring point acquisition requires high resolution and, in particular, an extremely accurate measuring instrument.

Surface waviness is a periodically recurring geometric deviation. The dominant waviness method according to VDA 2007 is suitable for evaluating surface waviness. This method makes it possible to identify a periodic deviation even at small wavelengths of just a few micrometers (μm).

Fig. 6: Result of a GDA/waviness analysis

Figure 6 shows the results of a profile and pitch measurement on a gear with 33 teeth. This diagram should not be confused with the results diagram of roll testing. The curve segments shown in red at the top are the results of the profile measurement of each gear tooth.

Each of these profile measurements is vertically shifted by the result of the pitch measurement.

The analysis shows three prominent waviness instances. The waviness shown at the top has a wavelength that corresponds to the entire reference circle perimeter of the gear.

This first order can always be attributed to runout. The first order is subtracted in the center section of Figure 6. Now, a fourth order is evident. It was caused by the collet of the fixture, which holds the workpiece in four locations and undergoes elastic deformation during the hard finishing.

The first and fourth orders are subtracted in the bottom segment. Now, a 28th order can be seen.

Since the component has 33 teeth, this cannot be the tooth mesh order. Rather, it is a machine vibration that is occurring 28 times per workpiece revolution.

Assuming that waviness does not only occur singularly on one gear tooth, but can be found on all teeth, a sufficiently reliable conclusion can be drawn as to whether or not noise-relevant orders are present by evaluating four profile and flank line measurements as well as the pitch measurement.

Since the evaluation is generated as part of the usual gear measurement without any additional effort, the waviness analysis of the gear measurement offers the potential to detect noise-critical gears at a very early stage.

For troubleshooting purposes and to precisely identify what critical orders are occurring, an

all-teeth measurement is essential.

This is the only way to detect noise-relevant deviations that do not occur periodically with tooth contact, but do occur periodically with rotation.

Both roll testing and the waviness analysis generate an order spectrum that provides quantitative insight into the running behavior of a gear. But what potential does each offer – and where are their limits? (See also Table 1.)

Tab. 1: Differences between roll testing and Gear Deviation Analysis processes

The GDA/waviness analysis generates an order spectrum that originates solely in the gear undergoing testing, whereas in roll testing, the master gear influences the result.

This places considerable demands on the tooth flanks of the master gear. But roll testing does include a large part of the tooth flank in the measurement – and not just the lines in the profile and flank line direction.

Another difference is the structure of the order spectra. The more teeth are measured, the more closely the structure of a GDA spectrum will match that of roll testing.

Low orders or orders that only periodically match the gear rotation, but not the tooth contact, are only detected by the GDA software if all teeth are measured. An even better match can be achieved if the orders resulting from the profile and pitch measurement are superposed on those from the flank line and pitch measurement during the GDA.

The amplitudes in the order spectra must differ due to the process. During roll testing, a wave is only detected in the tooth contact if the flank of the master gear can follow the wave trough of the test gear and does not bridge it.

A similar effect is known from roughness measurement when using different radii of the test needle. With the GDA software, this ball diameter effect plays a significantly smaller role. Thus, the amplitudes of the two order spectra will differ.

A look at specific example gears (z = 63, mn = 1.52 mm) illustrates the possibilities of the GDA software and the single-flank test (SFT) on the Höfler R 300 Cylindrical Gear Roll Testing Machine for identifying noise excitation-relevant geometry deviations.

The GDA is based on all-teeth measurements of pitch, profile and lead that were taken on a P 40 precision measuring center using a stylus with a 1 mm ball diameter. For the SFT measurement series, a z = 32 master gear (MSTR) was used. The profile radius of curvature on the MSTR reference circle is 9.627 mm.

The measurement results show that the reference gear essentially has a sinusoidal accumulated pitch error and a flank topography without waviness (see Figure 7). Accordingly, the order spectrum of the single-flank test at the top of the figure shows a prominent 1st order (O63) and a precipitous drop in the amplitudes of the higher-harmonic of fz. Similarly, in the GDA order spectrum, the 1st order is prominent, but the amplitudes of the higher harmonic of fz are significantly larger in the GDA order spectrum than in the spectrum of the single-flank test. This is due, among other things, to the different stylus radius and profile radius of curvature sizes. Between the orders of the 1st fz and its higher harmonic, no extremely significant intermediate orders, or sidebands, can be identified in either the SFT or the GDA spectrum.

Compared with the reference gear in Figure 7, Figure 8 shows a side-by-side comparison of the SFT and GDA order spectra for a gear that was ground with a defective, three-thread grinding worm.

Fig. 7: Comparison of SFT versus GDA using the example of a gear with sinusoidal accumulated pitch error and a flank topography without waviness

Fig. 8: Comparison of SFT versus GDA using a continuously generative-ground gear machined with a three-thread grinding worm as an example

Due to the whole-number transmission ratio between the number of workpiece teeth (z = 63) and the three-thread grinding worm, both the SFT spectrum and the GDA spectrum show prominent amplitudes for the 21st workpiece order and its multiples, in addition to the harmonics of the tooth-mesh order.

Figures 9 to 11 show what gears can look like if they have not been smoothly ground.

Some tooth flanks show shading produced by a lack of grinding (see Figure 9). Accordingly, there are two significantly different areas in the averaged workpiece rotation of the single-flank test (see Figure 10). In the corresponding order spectra of the SFT and the GDA (see Figure 11), in addition to the amplitudes of the 21st workpiece order and its multiples already known from the previous example (see Figure 8), other prominent amplitudes can also be recognized as sidebands to these orders and the tooth mesh harmonics.

Fig. 9: Tooth flanks of a continuously generative-ground gear that has not been smoothly ground in certain areas

The examples here show a good correlation between the results of the SFT and the GDA. Thus, both methods are suitable for identifying noise-relevant geometry deviations. Each has different advantages, however. Due to its significantly shorter measuring time, the single-flank test is well-suited to complete inline monitoring of the production process.

The GDA, on the other hand, is better suited to laboratory analyses due to its all-teeth measurement.

Fig. 10: SFT averaged workpiece rotation of a continuously generative-ground gear that has not been smoothly ground in certain areas

Fig. 11: Comparison of SFT versus GDA using a continuously generative-ground gear that has not been smoothly ground in certain areas as an example

Both roll testing and the waviness analysis are suitable for detecting gears that are critical from a noise perspective.

The informative value of an order spectrum goes far beyond the evaluation of a conventional gear measuring technique.

The appeal of the GDA software lies in the fact that it can be integrated into the process chain without any additional effort. Klingelnberg’s P-series Precision Measuring Centers provide clear indications of expected noise problems for each gear measured.

It must be mentioned that the structure of the order spectrum only attains its full informative value when an all-teeth measurement is performed. This is where the orders classified as critical by the EOL test appear, because they convert vibrations in the gearbox into airborne noise. Due to its short measuring time, the R 300 can be easily integrated into the production process. This permanently prevents quality slippage.

Thus gearbox noise is best determined with roll testing on the R 300. A Klingelnberg Precision Measuring Center then provides the critical geometric information for measures to remedy the noise excitation.