When it comes to crafting precision gears, gear grinding emerges as a crucial step in the manufacturing process. However, not all gear grinding services offer the same level of expertise, potentially compromising the quality of the final product. Understanding the significance of gear grinding and ensuring the involvement of experts from the outset can prevent costly errors and ensure superior gear quality.

Understanding Gear Grinding

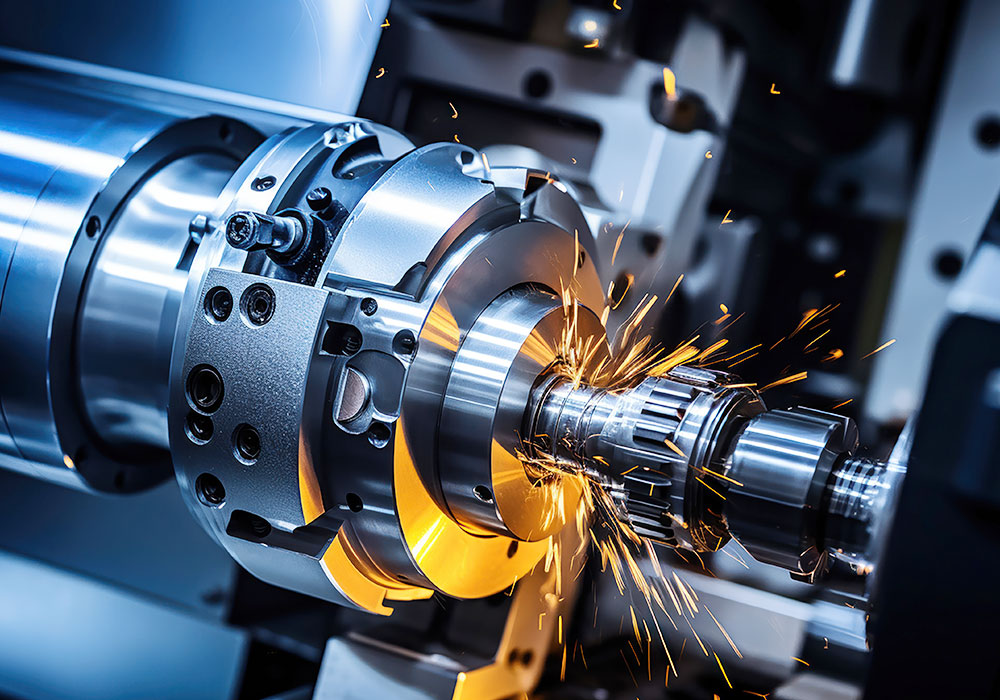

At its core, gear grinding involves using a rotating tool, typically equipped with abrasive grains, to refine the surface of workpieces. This process eliminates minor imperfections, leading to enhanced surface quality, shape, and dimensional accuracy. As the finishing touch in gear manufacturing, gear grinding plays a pivotal role in achieving high precision.

Why Initial Collaboration with Gear Grinding Experts Matters

Encountering issues with gears during the final stages of grinding can be a frustrating and costly setback. Rectifying these errors at this stage may be challenging, often resulting in scrapped gears, and wasted resources. Collaborating with gear grinding specialists from the inception of the manufacturing process ensures continuous oversight and adherence to quality standards, mitigating the risk of defects and minimising wastage.

Identifying Gear Grinding Expertise

When selecting a partner for precision gear grinding services, it’s essential to evaluate their expertise based on several key factors:

State-of-the-art grinding equipment equipped with advanced robotic automation is indispensable for achieving precision in gear manufacturing. A comprehensive fleet of high-performance grinders ensures operational efficiency and enables prompt order fulfilment, even in unforeseen circumstances.

A manufacturer’s reputation and track record are indicative of their reliability and proficiency in gear grinding. Years of experience in the industry, coupled with positive testimonials from satisfied customers, attest to the manufacturer’s commitment to quality and customer satisfaction.

The presence of a skilled team of gear-grinding specialists is paramount in maintaining consistency and excellence in gear manufacturing.

Manufacturers renowned for their expertise attract top talent and prioritise ongoing training and mentorship to uphold industry standards and foster a culture of excellence.

Gear grinding stands as a pivotal process in the realm of precision gear manufacturing, shaping the quality and functionality of crucial components across various industries.

As highlighted, the involvement of gear grinding experts from the outset is paramount to ensuring superior quality and minimizing costly errors. By understanding the significance of gear grinding and partnering with reputable specialists like Gear Motions, manufacturers can uphold stringent quality standards, optimize production efficiency, and ultimately deliver exceptional gears that meet the demands of modern applications.

As the cornerstone of gear manufacturing, gear grinding expertise continues to drive innovation, excellence, and reliability in the dynamic landscape of industrial production.